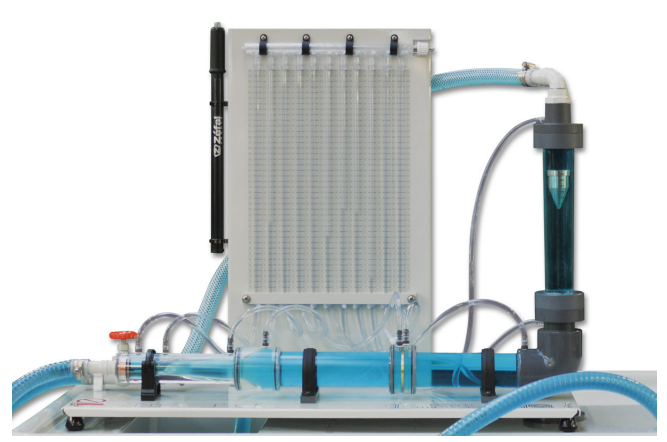

Pressure Measurement Bench

Description

Brand: Tecquipment

Model: H30

Country of Origin: United Kingdom

Manufacturer: United Kingdom

Features:

- Should enable a range of practical investigations into manometer and Bourdon gauge pressure measurement techniques

- The equipment should enable students to fully investigate and compare the operation and characteristics of inclined and U-tube manometers and Bourdon-type vacuum and pressure gauges

- It also should include a separate Bourdon gauge with dead-weight calibration apparatus, enabling clear observation of the Bourdon tube mechanism

- The apparatus should consist of two units:

- A manometers and gauges unit

- A Bourdon pressure gauge calibration unit

- The manometers and gauges unit should be a framed structure with a backboard, holding a:

- Vertical U-tube manometer

- U-tube manometer with an inclined limb

- Bourdon gauge for measuring vacuums

- Bourdon gauge for measuring positive pressure

- Syringe assembly for pressurizing and reducing pressure in the measurement devices

- Each gauge and manometer should have a delivery point to connect to the syringe using plastic tubing (should be included)

- All connections should be push-fit and T-pieces should be provided to enable two instruments to be connected to one point

- The Bourdon pressure gauge calibration unit should consist of a piston, which is free to move vertically, in a close-fitting cylinder

- A transparent, flexible hose should connect the cylinder to the Bourdon pressure gauge

- The gauge and cylinder should be mounted on a common flat base

- The internal mechanism of the gauge should be clearly visible through the transparent dial

- During test, calibration weights can be placed onto the loading platform, which is an integral part of the piston assembly

- All air should be expelled from the system through a purge hole in the upper part of the cylinder

- The apparatus should be manufactured using materials and finishes carefully chosen to give the fullest protection against corrosion

Experimental Capabilities:

- A range of investigations into common pressure measurement techniques, including:

- Comparison of pressure measurement by manometer and Bourdon gauge

- Calibration of a pressure gauge

- Determination of gauge errors as a function of true pressure

Technical Parameters:

- Required accessories: Selection of weights for Bourdon gauge dead weight calibration, ‘T’ pieces, artery clamps, funnel and nylon tubes

- Bourdon gauge scale: Graduated in 0 ~ 200kN.m-2 in 10kN.m-2 intervals

- Typical gauge error: 1kN.m-2 over the entire range

- Dead weight tester load: 5~5.5kg

- Bourdon tube arc: 270° (approx.)

- Supplied weights: 1kg x 4, 0.5kg x 2 and 0.2kg x 1

- Printed operation manual

Reviews

There are no reviews yet.